![]()

Ubi (Dioscorea alata L.) or yam is a vine which produces both aerial tubers called bulbils and underground tubers or roots. The bulbils weighing a few grams and to over a kilogram come out from the leaf axils three (3) months after planting. The underground tubers weighing one to six kilograms can be harvested six months after planting.

![]()

The ubi roots has 70 percent moisture and 28 percent starch. It also contains traces of fats, crude protein, sugar, crude fiber, ash and Vitamin C, B1 and B2.

Ubi is grown primarily for its roots or tubers. The tubers can be eaten boiled, baked, roasted, flakes, chips and can be processed into powder form. Dehydrated yam slices are used for the preparation of food such as ice cream, cakes, pastries and other dessert. The ubi skin or peeling can be used as a raw material for the manufacture of food coloring.

Recommended Varieties

- VU-1 (BASCO UBI)

| Yield |

: |

18-20 tons/ha |

| Dry Matter |

: |

28.80% |

| Starch |

: |

21.25% (wet basis) |

| Protein |

: |

1.55% (wet basis) |

| Maturity |

: |

29 weeks |

| Skin color |

: |

brown |

| Cortex color |

: |

white with purplish flesh/tinge |

| Growth habit |

: |

green with purplish leaf veins, nodes and petiole ends |

- VU-2 (ZAMBALES UBI)-LA 167

| Yield |

: |

16.08 tons/ha |

| Dry Matter |

: |

30.49% |

| Protein |

: |

1.33% |

| Maturity |

: |

29 weeks |

| Skin color |

: |

brown |

| Cortex color |

: |

purple |

| Growth habit |

: |

twinning |

| Foliage color |

: |

green with purplish leaf veins, nodes and petiole ends |

| Reaction to disease |

: |

Resistant to foliar fungal disease |

- VU-3 (LEYTE)-LA 100

| Yield |

: |

21.26 tons/ha |

| Dry Matter |

: |

30.10% |

| Starch |

|

20.96% |

| Protein |

: |

1.52% |

| Maturity |

: |

31 weeks |

| Skin color |

: |

brown with blackish tinge |

| Cortex color |

: |

cream to pink |

| Flesh color |

: |

white |

| Growth habit |

: |

twinning |

| Foliage color |

: |

green with light green veins, petiole ends |

- KINAMPAY VARIETY

Kinampay Variety is known for its sweet aroma and good taste and dubbed as the "Queen of Philippine Yams" which has smooth and round roots. Ubing Kinampay is classified into five (5) varieties namely;

| Original Kinampay |

: |

reddish purple flesh |

| Kabus-ok |

: |

white flesh with large roots |

| Tamisan |

: |

reddish white flesh and sweeter in taste |

| Binanag |

: |

creamy-white flesh and elongated |

| Binato |

: |

big and hard root with whitish flesh color |

Other local cultivars are Binalog, Ubsah, Appari, Negro, Alabat, Kameral I and Kameral II.

Soil and Climatic Requirement

Ubi thrives anywhere in the Philippines and in a wide range of soil types and elevation because it can tolerate adverse conditions such as droughts and pest infestations. However, it thrives best in sandy loam or silt loam fertile, well-drained soil and temperature ranging from 25°C to 30°C. Ubi needs ample moisture throughout the growing season.

The crop can be grown anytime of the year but for best results, planting should be done at the beginning or just after the rainy season when it can obtain all the moisture it needs for growth.

Cultural Management

Land Preparation

Tillage - Two plowings and two harrowings are usually enough for ubi for a field that has been previously cultivated. Plow deeply. Ubi needs a deep loose soil. Harrow along and across the length of the field to pulverize the soil.

Seedbed - Plant ubi on flat or ridged seedbeds. These are preferable to other types of seedbeds;

If flat beds are used, plant after the last harrowing.

On sloping or rolling fields, contour the ridges to minimize soil erosion.

Crop Establishment

Setts Preparation

About 20,000 to 27,778 setts are needed for a hectare of land. There are four types of setts: head, middle, tail and whole. The first three are prepared by cutting large tubers into pieces. The fourth type refers to the whole small tuber. Setts should be obtained from healthy tubers of healthy plants.

Slice large tubers into setts weighing from 60g to 250g. Do not slice tubers weighing less than 60g. Be sure that each setts has enough skin area. Treat cut sides of setts with ash or fungicide. Air or sun-dry the setts until cuts are dry. After drying, setts maybe pre-sprouted or planted directly.

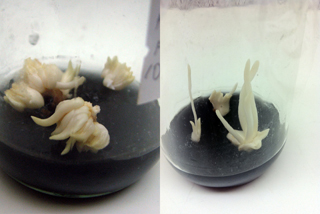

Pre-sprouting Setts

Sprouts emerge from setts about 2-3 weeks after planting. Pre-sprouting the setts before planting is recommended to minimize weeding expenses before sprout emergence.

For a pre-sprouting bed, dig a shallow ditch in a shady area or clear the ground in a shady area by removing stones, weeds and debris.

Plant setts cut from large tubers either skin up or skin sideways. Whole tubers measuring 60 to 250g either crown up or crown side ways should be planted. Then cover the setts with a thin layer of soil. Water the pre-sprouting bed at least one a week until most of the setts have sprouted.

Preparing Pre-sprouted Setts for Planting

With pre-sprouted setts, planting may either be staggered or done at one time.

Staggered Planting

The following activities must be performed in all batches of planting:

a. Remove from pre-sprouting bed setts that have emerged to prevent sprouts from growing too long.

b. Place the sprouted setts on a platform in a shady area.

c. Repeat the process every week or every two weeks until the desired number of sprouted setts for one batch of planting is obtained. Plant before the sprouts become too long to transport or before sprouts start wilting.

One-time Planting

The procedure of sett preparation is essentially the same as that fro staggered planting. One-time planting is done only after most of the viable setts have produced sprouts. At this time, sprouts of some setts are already very long. Cut along sprouts before transporting setts to the field for planting.

Planting

Planting is done from March to June. However, planting time for ubi depends upon the time tuber dormancy is broken and the start of rain in the area.

a. Non-sprouted Setts

Plant setts in the seedbed at a distance of 1m x 50cm or 60cm x 60cm. Plant the setts 10cm deep during the rainy season and 15cm during dry season, especially if the field will not be mulched. Setts can be planted in any position

b. Pre-sprouted Setts

Plant the setts at the start of rain if it is not possible to irrigate or mulch the field. Plant the setts in the seedbed at a depth of 10cm and a distance of 1m x 50cm or 60cm x 60cm. Be sure to orient the sprout upward in planting.

Divide the field into four to six section and if staggered planting is applied. Each section is intended for one planting batch. The size and the time to prepare each section depend upon the rate of sett sprouting.

Mulching

Mulch the field to reduce soil temperature, conserve soil moisture, increase organic matter content of the soil and suppress weed growth.

Use dry coconut fronds, corn stalks, rice straw and other similar materials in mulching. See to it that these materials are free from weed seeds.

Mulch the field just after planting. Make the mulch thick if rice straw or any material that rot easily are used.

Weeding

With non-sprouted setts and without mulching, 3-5 weedings are needed. With pre-sprouted setts and with mulching, only two weedings at 2-month intervals are needed.

While plants are still short and unstaked or if the stake set-up allows, use animal- drawn implements to control weeds in an unmulched fields. Vines crossing the path of the animal should be lifted and placed along the rows before plowing.

Use handtools to weed the field once plants are already staked and the stake set-up does not allow the use of animal-drawn implement or if the field is mulched.

With non-presprouted setts and without mulching pre-emergence herbicides applied within one week after planting, maybe used to control weeds.

Staking

Place a stake for each plant before vines start crawling on the ground. Stakes should be 1-2m long. Bamboo, wood, cassava stalks, talahib stalks, or any similar materials that can support the ubi vines which can be used as stakes for at least seven months. If cassava stalk is used, it should be set up in an inverted position (young end down) to prevent the stalk from producing new shoots.

Training Vines

Ubi vines twines to the right. When vines start trailing on the ground, train the vines climb their respective stakes. Also, train the vines again when branches start crossing the rows, especially when weeding and hilling-up operations by using animal-drawn implements.

Nutrient Management

A hectare of ubi can remove about 128 kg nitrogen, 17kg phosphorus and 162 kg potassium from the soil. Collect soil samples from the field first before applying fertilizer and submit for soil analysis to the Bureau of Soils and Water Management.

a. Inorganic Fertilization - The recommended amount of fertilizer should be split into two, one half to be applied about one month after emergence (or one month after planting of pre-sprouted setts) and the other half about 2 months after the first application. Apply the fertilizer following the band method and placing the fertilizer about 10 cm away from the plants.

b. Organic Fertilization - Use of compost which is a mixture of decayed organic matter from plant parts and animal manure. Mix the compost with the soil during land preparation or place the compost just below the setts during the planting.

Harvest Management

Ubi is ready for harvest when its foliage is already yellowing or drying up. For most varieties, the drying up period of the foliage starts in late November and lasts until January the following year. Tubers intended for sett production should be harvested at the later part of the drying up period. However, tubers for consumption or for selling in the market should be harvested earlier, even before foliages dries up.

Harvesting ubi in sandy soil, use sturdy sticks sharpened at one end to dig out the tuber, remove soil particles that cling to the tuber and cut the vine at the base. For clayey and varieties with deeply buried tubers, use ubi harvester developed by the Philippine Rootcrops Research Training Center.

Prior to transporting, separate healthy tubers from diseased ones. Tubers should be arranged in a container in such a way that rubbing of tubers inside the container can be prevented. Place tubers in rattan baskets or in bamboo or wooden crates lined with soft material such as paper, banana leaves or straw. Arrange 2-4 layers of tubers in the container, the bigger the tubers the fewer the number of layers. Place soft material between layers and between tubers in a layer to serve as cushion.

Storage

Tubers need to be stored in a bam while they are not yet marketed nor consumed whereas tubers intended for setts need to be stored until planting or replanting time. Storage structure for ubi should be shaded and adequately ventilated.

There are three methods of storage:

Barn storage - tubers are tied to vertically arranged poles held together by sturdy horizontal poles. Durable tying materials like rope are use din tying the tubers to the poles. The vertical poles are arranged about 50cm apart.

Platform storage - large tubers are placed in one layer on raised platforms constructed in the shed. Small tubers are arranged in 2-3 layers.

Shelf Storage - Tubers are placed on several decks of platforms instead of just one deck.

References:

Agriculture and Fisheries Information Service-Department of Agriculture, Elliptical Road, Diliman, Quezon City 1100, April 2004

Source: bar.gov.ph

Photo by AlmaGamil_Philippines

Photo by AlmaGamil_Philippines  [/caption]

Pili pulp oil is clear and may appear greenish yellow. It has 56.7% oleic glycerides, 13.5% linoleicglycerides and 29.3% saturated fatty acids. Based on the analysis done by DOST Region V, the oil has very low free fatty acid (FFA) content of 0.06% and moisture content of only 0.04% which assures longer shelf life.

Properties and Composition

Compared to olive oil, pili pulp oil has more beta carotene, a known source of Vitamin A, caroteneoids, tocopherols (vitamin E) and phytosterols. These substances are antioxidants that protect cells from oxidation and neutralize unstable free radicals. Pili pulp oil is also a good source of protein, iodine and calcium.

Uses

Pili oil can be used in salad dressings, fish canning, baking and in other food preparations. The oil contains natural germicide, anti-bacterial and anti-inflammatory agents effective in healing wounds and allergies. It is also suitable for people with delicate skin and helps prevent wrinkles with its anti-aging element. It also prevents acne and pimples. The oil is now used as a main ingredient in bath soaps and massage oil, and as an additive in anti-dandruff shampoo.

Indigenous knowledge gathered attests to its efficacy in treating skin diseases such as scabies and its deworming capability for livestock such as pigs and chicken.

Laboratory animal studies revealed that pili oil is effective in managing cholesterol and weight.

Source: bcarrd.com

[/caption]

Pili pulp oil is clear and may appear greenish yellow. It has 56.7% oleic glycerides, 13.5% linoleicglycerides and 29.3% saturated fatty acids. Based on the analysis done by DOST Region V, the oil has very low free fatty acid (FFA) content of 0.06% and moisture content of only 0.04% which assures longer shelf life.

Properties and Composition

Compared to olive oil, pili pulp oil has more beta carotene, a known source of Vitamin A, caroteneoids, tocopherols (vitamin E) and phytosterols. These substances are antioxidants that protect cells from oxidation and neutralize unstable free radicals. Pili pulp oil is also a good source of protein, iodine and calcium.

Uses

Pili oil can be used in salad dressings, fish canning, baking and in other food preparations. The oil contains natural germicide, anti-bacterial and anti-inflammatory agents effective in healing wounds and allergies. It is also suitable for people with delicate skin and helps prevent wrinkles with its anti-aging element. It also prevents acne and pimples. The oil is now used as a main ingredient in bath soaps and massage oil, and as an additive in anti-dandruff shampoo.

Indigenous knowledge gathered attests to its efficacy in treating skin diseases such as scabies and its deworming capability for livestock such as pigs and chicken.

Laboratory animal studies revealed that pili oil is effective in managing cholesterol and weight.

Source: bcarrd.com

Photo by

Photo by

Photo by

Photo by

The spathe is a modified leaf typically heart shape. It comes in different colors - pink, white, green white and red.

Anthurium Production Guide

Recommended Varieties

Cultivars grown locally are the following:

Nitta (orange)

Kaumana (red)

Ozaki (dark pink)

Kaonaiwan (white)

Pink Exotica (light pink)

Other varieties introduced from Holland:

Margaretha (white)

Midori (green)

Mauricia (dark pink)

Claudia (red)

Leigh (beige)

Cultural Management

Methods of propagation

division or separation of suckers

top cuttings

tissue culture

Planting

Anthurium can be grown in raised bed or clay pots. Larger pots are used for larger varieties. Enough holes in the bottom or sides of the pots should be provided for efficient drainage. The size of beds depends on the growers but the ideal distance of planting should be 1 meter to accommodate nine mature plants per square meter.

Growth Medium

The selection of the growth medium depends on the availability, cost and ease of handling.

The most common media used are:

coconut husks

coir dust

red or black cinder

Light Requirement

The light requirement ranges from 60 - 75% shade. Three to four layers of net 10 feet above the plants should be installed.

Temperature Requirement

The best temperature in growing anthurium ranges from 10 - 20°C (night temperature) and 27 - 30°C (day temperature).

Water Requirement

The amount and frequency of watering depends on the prevailing climatic condition in the production area, medium and degree of shading. Anthurium needs water during all the stages of growth. It requires high relative humidity

Fertilizer requirements

Both inorganic and organic fertilizers may be used in anthurium. Complete fertilizers such as 16-16-16, 30-10-10 and 10-20-30 at the rate of 1 tablespoon per gallon of water sprayed or drenched on the medium.

Pest and disease control

PESTS

Anthurium flowers are susceptible to pests that such as aphids, scales, spider mite, mealybugs and thrips. Thrips and mealybugs are found on new growth. Aphids feed on the flower buds. Symptoms of anthurium flower that infested by

aphids include yellowing, distortion of leaves and poor growth. Scales seem to be particularly fond of the tough bird nest type. Symptoms of anthurium flower that infested by scale insects include infested stems and leaves.

Control measures

There are some “insecticidal soaps” which work well on the soft insects, but scales may need stronger insecticide. The best method of insect control is to monitor anthurium fl ower and treat it before the insect get out of hand. One of the best ways to stay clear of the use of chemicals is with periodic wiping of the foliage and a gentle spray using water.

FUNGAL DISEASE: RHIZOCTINIA

The biggest disease problem that infects anthurium flower is rhizoctinia. The rhizoctinia is caused by high temperature and humidity coupled with soil that is poorly drained. Over watering should be avoided and if anthurium flower is replanted, a well drained soil should be used in order to prevent rhizoctinia disease. Rhizoctinia can also be controlled by a wide range of fungicides chemicals. The best approach is prevention via cultural practices. The symptoms of rhizoctonia disease include falling of anthurium flowers’ tree especially during rainy season.

Harvesting

Anthurium flowers are generally harvested when the spadix is almost fully developed. Flowers picked too early wilt quickly. Development of true flowers on spadix is also used as a criterion for determining the harvest stage. The anthurium flowers are harvested after the unfolding of the spathe is completed. Anthurium flowers are best harvested in the morning. The anthurium flowers are harvested by hand using sharp secateur scissor. About 8 - 12 flowers per plant are obtained annually.

Classification of Flowers

Flowers are sold according to sizes of the spathe (length across the broadest part)

extra large (10.0 cm and above)

large (8.0 - 8.5 cm)

medium (7.0 - 7.5 cm)

small (6.0 - 6.5 cm)

miniature (5.5 cm and below)

Packing

Anthurium flowers are packed in plastic sleeves with stem ends insert in plastic tube with water. Flowers are also packed in boxes containing moistened shredded paper to prevent dehydration.

References

Bureau of Plant and Industry Technoguides.

Sources: bar.gov.ph, nda.agric.za

The spathe is a modified leaf typically heart shape. It comes in different colors - pink, white, green white and red.

Anthurium Production Guide

Recommended Varieties

Cultivars grown locally are the following:

Nitta (orange)

Kaumana (red)

Ozaki (dark pink)

Kaonaiwan (white)

Pink Exotica (light pink)

Other varieties introduced from Holland:

Margaretha (white)

Midori (green)

Mauricia (dark pink)

Claudia (red)

Leigh (beige)

Cultural Management

Methods of propagation

division or separation of suckers

top cuttings

tissue culture

Planting

Anthurium can be grown in raised bed or clay pots. Larger pots are used for larger varieties. Enough holes in the bottom or sides of the pots should be provided for efficient drainage. The size of beds depends on the growers but the ideal distance of planting should be 1 meter to accommodate nine mature plants per square meter.

Growth Medium

The selection of the growth medium depends on the availability, cost and ease of handling.

The most common media used are:

coconut husks

coir dust

red or black cinder

Light Requirement

The light requirement ranges from 60 - 75% shade. Three to four layers of net 10 feet above the plants should be installed.

Temperature Requirement

The best temperature in growing anthurium ranges from 10 - 20°C (night temperature) and 27 - 30°C (day temperature).

Water Requirement

The amount and frequency of watering depends on the prevailing climatic condition in the production area, medium and degree of shading. Anthurium needs water during all the stages of growth. It requires high relative humidity

Fertilizer requirements

Both inorganic and organic fertilizers may be used in anthurium. Complete fertilizers such as 16-16-16, 30-10-10 and 10-20-30 at the rate of 1 tablespoon per gallon of water sprayed or drenched on the medium.

Pest and disease control

PESTS

Anthurium flowers are susceptible to pests that such as aphids, scales, spider mite, mealybugs and thrips. Thrips and mealybugs are found on new growth. Aphids feed on the flower buds. Symptoms of anthurium flower that infested by

aphids include yellowing, distortion of leaves and poor growth. Scales seem to be particularly fond of the tough bird nest type. Symptoms of anthurium flower that infested by scale insects include infested stems and leaves.

Control measures

There are some “insecticidal soaps” which work well on the soft insects, but scales may need stronger insecticide. The best method of insect control is to monitor anthurium fl ower and treat it before the insect get out of hand. One of the best ways to stay clear of the use of chemicals is with periodic wiping of the foliage and a gentle spray using water.

FUNGAL DISEASE: RHIZOCTINIA

The biggest disease problem that infects anthurium flower is rhizoctinia. The rhizoctinia is caused by high temperature and humidity coupled with soil that is poorly drained. Over watering should be avoided and if anthurium flower is replanted, a well drained soil should be used in order to prevent rhizoctinia disease. Rhizoctinia can also be controlled by a wide range of fungicides chemicals. The best approach is prevention via cultural practices. The symptoms of rhizoctonia disease include falling of anthurium flowers’ tree especially during rainy season.

Harvesting

Anthurium flowers are generally harvested when the spadix is almost fully developed. Flowers picked too early wilt quickly. Development of true flowers on spadix is also used as a criterion for determining the harvest stage. The anthurium flowers are harvested after the unfolding of the spathe is completed. Anthurium flowers are best harvested in the morning. The anthurium flowers are harvested by hand using sharp secateur scissor. About 8 - 12 flowers per plant are obtained annually.

Classification of Flowers

Flowers are sold according to sizes of the spathe (length across the broadest part)

extra large (10.0 cm and above)

large (8.0 - 8.5 cm)

medium (7.0 - 7.5 cm)

small (6.0 - 6.5 cm)

miniature (5.5 cm and below)

Packing

Anthurium flowers are packed in plastic sleeves with stem ends insert in plastic tube with water. Flowers are also packed in boxes containing moistened shredded paper to prevent dehydration.

References

Bureau of Plant and Industry Technoguides.

Sources: bar.gov.ph, nda.agric.za

There are times when the price of tomatoes is very low because there is an over supply of production which causes great loss for farmers. So most of the time, tomatoes just rot in the field, causing financial losses. Outstanding young farmer of the Philippines Romeo Yapit of Purac, Sinait, Ilocos has a solution to this problem.

To slow the ripening of tomatoes, he arranges the tomatoes and covers half of the number with uncooked rice hull and the other half with carbonized rice hull. It would take five months for the tomatoes to ripen. By that time, it's rainy season already when tomatoes can be sold at a higher price.

There are times when the price of tomatoes is very low because there is an over supply of production which causes great loss for farmers. So most of the time, tomatoes just rot in the field, causing financial losses. Outstanding young farmer of the Philippines Romeo Yapit of Purac, Sinait, Ilocos has a solution to this problem.

To slow the ripening of tomatoes, he arranges the tomatoes and covers half of the number with uncooked rice hull and the other half with carbonized rice hull. It would take five months for the tomatoes to ripen. By that time, it's rainy season already when tomatoes can be sold at a higher price.

The oriental fruitfly (Bactosera philippinesis) is a major concern in the Philippines, particularly in mango production. The country is producing thousands of metric tons of mango a year mostly fresh or processed. But out of this, only 8% of the total production is exported due to fruitfly infestation and the ineffective means of controlling them.

The infestation of fruitfly in mangoes is manifested by punctures in the flesh. Microorganisms penetrate into the flesh damaging the skin and causing the flesh to rot.

Researchers from the Mariano Marcos State University (MMSU) headed by Leticia A. Lutap, Salud F. Barroga and Marissa I. Atis conducted a field study on how to deliberately eliminate the fruitfly.

The study determined which particular seasons are the adult fruitfly abundant, the effects of the environment factors to the fluctuation of the adult fruitfly, and the most effective time of controlling fruitfly.

Through the years, a lot of measures have been identified to control fruitfly infestation. For instance, the integrated control method, which was introduced in Taiwan since 1975 has been used in the country up the 1980's to eradicate this pest. The method used sterile flies, chemicals like methyl eugenol.

But the problem is on the application of the technologies. Farmers are not familiar on the best time to apply them. It is important to know the time and the extent of applying the control measure since fruitfly also infests other fruits in season such as guava, santol, jackfruit, papaya, siniguelas and avocado.

Fruitfly could reduce the yield of mango by as much as 23 percent. To avoid this loss, researchers from MMSU were able to develop a bait trap that wipes out the insects.

The bait trap is made of a plastic container. Inside is a fireboard, about an inch, which attached to the plastic container using a hook wire. To lure the fruitfly, methyl eugenol (PME) was used an poisoned with insecticide. Methyl eugenol is a hormone that attracts male fruitfly. The bait is soaked into the fireboard once in ten days and then installed on the mango trees.

After a year of investication results of the study showed that the fruitfly infestation was surely lessen. It reduced the fruitfly population to as much as 86%.

The researchers recommend the use of bait traps since this is not tedious unlike other control measures. Mango is not a yeat round crop, so application should be done during January to July only when population of fruitfly is its peak.

Source:

"Mango Fruitfly: Population Dynamics and Effectiveness of Bait Trap for its Control" by Leticia A. Lutap, Salud F. Barroga and Marissa I. Atis of Mariano Marcos State University. Batac 2906 Ilocos Norte. For more information, contact them at telephone nos. (077) 792-3131 or 792-3447 or email ilarrdec@laoag.amanet.net

By: Rita T. dela Cruz, BAR Chronicle, February 2002 Issue (Vol. 3 No. 3-4)

The oriental fruitfly (Bactosera philippinesis) is a major concern in the Philippines, particularly in mango production. The country is producing thousands of metric tons of mango a year mostly fresh or processed. But out of this, only 8% of the total production is exported due to fruitfly infestation and the ineffective means of controlling them.

The infestation of fruitfly in mangoes is manifested by punctures in the flesh. Microorganisms penetrate into the flesh damaging the skin and causing the flesh to rot.

Researchers from the Mariano Marcos State University (MMSU) headed by Leticia A. Lutap, Salud F. Barroga and Marissa I. Atis conducted a field study on how to deliberately eliminate the fruitfly.

The study determined which particular seasons are the adult fruitfly abundant, the effects of the environment factors to the fluctuation of the adult fruitfly, and the most effective time of controlling fruitfly.

Through the years, a lot of measures have been identified to control fruitfly infestation. For instance, the integrated control method, which was introduced in Taiwan since 1975 has been used in the country up the 1980's to eradicate this pest. The method used sterile flies, chemicals like methyl eugenol.

But the problem is on the application of the technologies. Farmers are not familiar on the best time to apply them. It is important to know the time and the extent of applying the control measure since fruitfly also infests other fruits in season such as guava, santol, jackfruit, papaya, siniguelas and avocado.

Fruitfly could reduce the yield of mango by as much as 23 percent. To avoid this loss, researchers from MMSU were able to develop a bait trap that wipes out the insects.

The bait trap is made of a plastic container. Inside is a fireboard, about an inch, which attached to the plastic container using a hook wire. To lure the fruitfly, methyl eugenol (PME) was used an poisoned with insecticide. Methyl eugenol is a hormone that attracts male fruitfly. The bait is soaked into the fireboard once in ten days and then installed on the mango trees.

After a year of investication results of the study showed that the fruitfly infestation was surely lessen. It reduced the fruitfly population to as much as 86%.

The researchers recommend the use of bait traps since this is not tedious unlike other control measures. Mango is not a yeat round crop, so application should be done during January to July only when population of fruitfly is its peak.

Source:

"Mango Fruitfly: Population Dynamics and Effectiveness of Bait Trap for its Control" by Leticia A. Lutap, Salud F. Barroga and Marissa I. Atis of Mariano Marcos State University. Batac 2906 Ilocos Norte. For more information, contact them at telephone nos. (077) 792-3131 or 792-3447 or email ilarrdec@laoag.amanet.net

By: Rita T. dela Cruz, BAR Chronicle, February 2002 Issue (Vol. 3 No. 3-4)

The ubi roots has 70 percent moisture and 28 percent starch. It also contains traces of fats, crude protein, sugar, crude fiber, ash and Vitamin C, B1 and B2.

Ubi is grown primarily for its roots or tubers. The tubers can be eaten boiled, baked, roasted, flakes, chips and can be processed into powder form. Dehydrated yam slices are used for the preparation of food such as ice cream, cakes, pastries and other dessert. The ubi skin or peeling can be used as a raw material for the manufacture of food coloring.

Recommended Varieties

The ubi roots has 70 percent moisture and 28 percent starch. It also contains traces of fats, crude protein, sugar, crude fiber, ash and Vitamin C, B1 and B2.

Ubi is grown primarily for its roots or tubers. The tubers can be eaten boiled, baked, roasted, flakes, chips and can be processed into powder form. Dehydrated yam slices are used for the preparation of food such as ice cream, cakes, pastries and other dessert. The ubi skin or peeling can be used as a raw material for the manufacture of food coloring.

Recommended Varieties

A. pintoi is related to the peanut food legume (Arachis hypogaea) and is a forage legume that has become more than just a feed source for animals.

Its stunning yellow flowers or florets and dense clover-shaped foliage provide a spectacular aesthetic value among gardeners and plant enthusiasts earning it the moniker “golden glory”.

Arachis what?

Arachis pintoi is one of the forage legumes considered in the livestock and poultry industry as a protein-fiber source component in the animal diet. It is very good for native or free-range chicken and ducks. Pigs can also be fed with Arachis. For ruminants, it is recommended for cut-and-carry system and as supplement or component with grass and tree leaves. It has a nutritive value of 13?25% crude protein and 60?70% dry matter digestibility.

Popularly known among local gardeners as peanut plant, arachis, and “mani-manian”, among other names, it is believed to have come from South America, domesticated and further developed through research.

The plant was introduced to the Philippines in the 80s through foreign-funded feed resource and forage projects.

With its very unique characteristics and uses, its popularity has grown since then. Aside from being a very good source of high quality protein feed for the livestock diet, it can also be used as cover crop to control weeds.

Studies also show that Arachis improves soil fertility and condition. The plant spreads fast, thus easily covering the ground and thus helping control soil erosion.

Since Arachis is a relative of the food peanut, it produces seed underground making harvesting of its seed is difficult. But the plant can be established through seed provided good seed is available. In fact, the plant also grows even in moderately fertile soils but best suited to the wet with short or no dry season.

One of the limitations of Arachis is that it cannot withstand heavy grazing and high animal stocking rate. However, this is not a concern of landscape architects who use the Arachis for a different purpose.

A. pintoi is related to the peanut food legume (Arachis hypogaea) and is a forage legume that has become more than just a feed source for animals.

Its stunning yellow flowers or florets and dense clover-shaped foliage provide a spectacular aesthetic value among gardeners and plant enthusiasts earning it the moniker “golden glory”.

Arachis what?

Arachis pintoi is one of the forage legumes considered in the livestock and poultry industry as a protein-fiber source component in the animal diet. It is very good for native or free-range chicken and ducks. Pigs can also be fed with Arachis. For ruminants, it is recommended for cut-and-carry system and as supplement or component with grass and tree leaves. It has a nutritive value of 13?25% crude protein and 60?70% dry matter digestibility.

Popularly known among local gardeners as peanut plant, arachis, and “mani-manian”, among other names, it is believed to have come from South America, domesticated and further developed through research.

The plant was introduced to the Philippines in the 80s through foreign-funded feed resource and forage projects.

With its very unique characteristics and uses, its popularity has grown since then. Aside from being a very good source of high quality protein feed for the livestock diet, it can also be used as cover crop to control weeds.

Studies also show that Arachis improves soil fertility and condition. The plant spreads fast, thus easily covering the ground and thus helping control soil erosion.

Since Arachis is a relative of the food peanut, it produces seed underground making harvesting of its seed is difficult. But the plant can be established through seed provided good seed is available. In fact, the plant also grows even in moderately fertile soils but best suited to the wet with short or no dry season.

One of the limitations of Arachis is that it cannot withstand heavy grazing and high animal stocking rate. However, this is not a concern of landscape architects who use the Arachis for a different purpose.

There are two varieties of Marang that are locally available and are commercially sold in the market: brown and evergreen. The brown variety has light to dark brown peel with white to off-white pulp. The average fruit size weighs 1,250-1,700 grams and has 6-10 percent edible portion. Meanwhile, the evergreen variety has green to light green peel and white pulp. It is heavier (1,300-1,800 grams), has more edible portion (10-15 percent), and is sweeter than the brown variety.

Going beyond its thorny and unsightly appearance, Marang has become a favorite fruit for those who have tasted it. It is known for its appetizing taste, strong but fragrant sugary smell, and nutritive value. It contains protein, fat, carbohydrates, crude fiber, ash, calcium, phosphorus, iron, retinol, beta-carotene, vitamin A, thiamine, riboflavin, niacin, and ascorbic acid.

But this fruit is seasonal. It is only available from May to September. After harvest, a mature fruit becomes highly perishable, lasting for 2-3 days only. Once opened, a ripe Marang must be consumed immediately because it can easily lose its flavor and it oxidizes causing the pulp to brown. It was due to the seasonality and perishability of Marang that this fruits is undervalued and underutilized. Given its high demand, its short shelf life hinders its market potential.

To address this, a group of researchers from the University of Southern Mindanao Agricultural Research Center (USMARC) led by Dr. Emma K. Sales, implemented the project titled “Pilot Testing of Postharvest Technologies and Product Diversification of Marang”. This research initiative, funded by the Bureau of Agricultural Research (BAR) and the High Value Commercial Development Program (HVCDP) of the Department of Agriculture (DA), looked into the possibility of making processed products from Marang and making them readily available even during off-season. The result of this project is also seen to encourage growers, farmers, enthusiasts, and

There are two varieties of Marang that are locally available and are commercially sold in the market: brown and evergreen. The brown variety has light to dark brown peel with white to off-white pulp. The average fruit size weighs 1,250-1,700 grams and has 6-10 percent edible portion. Meanwhile, the evergreen variety has green to light green peel and white pulp. It is heavier (1,300-1,800 grams), has more edible portion (10-15 percent), and is sweeter than the brown variety.

Going beyond its thorny and unsightly appearance, Marang has become a favorite fruit for those who have tasted it. It is known for its appetizing taste, strong but fragrant sugary smell, and nutritive value. It contains protein, fat, carbohydrates, crude fiber, ash, calcium, phosphorus, iron, retinol, beta-carotene, vitamin A, thiamine, riboflavin, niacin, and ascorbic acid.

But this fruit is seasonal. It is only available from May to September. After harvest, a mature fruit becomes highly perishable, lasting for 2-3 days only. Once opened, a ripe Marang must be consumed immediately because it can easily lose its flavor and it oxidizes causing the pulp to brown. It was due to the seasonality and perishability of Marang that this fruits is undervalued and underutilized. Given its high demand, its short shelf life hinders its market potential.

To address this, a group of researchers from the University of Southern Mindanao Agricultural Research Center (USMARC) led by Dr. Emma K. Sales, implemented the project titled “Pilot Testing of Postharvest Technologies and Product Diversification of Marang”. This research initiative, funded by the Bureau of Agricultural Research (BAR) and the High Value Commercial Development Program (HVCDP) of the Department of Agriculture (DA), looked into the possibility of making processed products from Marang and making them readily available even during off-season. The result of this project is also seen to encourage growers, farmers, enthusiasts, and

Today, defatted soybean meal is the most common, low-cost food for fish. However, soybean meal is not the natural diet of fish because it lacks in key compounds required for proper fish nutrition. Thus, the use of soybean meal presents a major limitation in providing healthy growth conditions in Philippine aquaculture. The challenge, therefore, is to provide the ideal natural foods for fish such as microalgae at a competitive price, high quality, and adequate quantity.

To address this, the Bureau of Agricultural Research (BAR), funded a project titled, “Development of Technology for Efficient Microalgae Production: Photobioreactor Design, Feed and High-value Metabolites” that aimed to provide superior fish food through the development of local microalgae. Under the leadership of phycologist and chemist professor, Dr. Fabian M. Dayrit of the Ateneo de Manila (ADMU), he developed a technology that is simple, reliable and efficient photobioreactor (PBR) design system to maximize the yield and optimized culture conditions for microalgae production of Spirulina.

Today, defatted soybean meal is the most common, low-cost food for fish. However, soybean meal is not the natural diet of fish because it lacks in key compounds required for proper fish nutrition. Thus, the use of soybean meal presents a major limitation in providing healthy growth conditions in Philippine aquaculture. The challenge, therefore, is to provide the ideal natural foods for fish such as microalgae at a competitive price, high quality, and adequate quantity.

To address this, the Bureau of Agricultural Research (BAR), funded a project titled, “Development of Technology for Efficient Microalgae Production: Photobioreactor Design, Feed and High-value Metabolites” that aimed to provide superior fish food through the development of local microalgae. Under the leadership of phycologist and chemist professor, Dr. Fabian M. Dayrit of the Ateneo de Manila (ADMU), he developed a technology that is simple, reliable and efficient photobioreactor (PBR) design system to maximize the yield and optimized culture conditions for microalgae production of Spirulina.

Spirulina (Arthrospira platensis) or the blue-green photosynthetic microalgae, known as the highest natural protein source, contains about 55-70 percent essential protein profile with a complete set of key compounds such as amino acids, polyunsaturated fatty-acids (PUFA’s), carotenoids, and vitamins A, C, D, E, B12 or cobalamin that boost the required nutritional diet of fish. One of the characteristics of this quality feed is the presence of natural constituents that has high value of nutraceuticals. These compounds include omega-3 fatty acids, carbohydrates, dietary minerals, and phycobiliproteins.

Due to its boundless nutrient contents, Dr. Dayrit highlighted the main benefits of feeding Spirulina for aquaculture purposes. Among the benefits include: 1) increase and give a more uniform growth rate for fish; 2) improve the digestion; as a result of more nutrition are extracted from the food and there are no indigestible components; 3.) boost the immune system and aid prevention of swollen abdomens due to blocked intestinal passages; and 4) enhance production of special enzymes that break down digested fats into energy rather than letting them build up in the fishes body.

Seeing its importance, Dr. Dayrit and his team fabricated an optimized PBR system and culture condition for the production of Spirulina. Unlike other PBR designs for algae growth, the features of developed enhance PBR are inexpensive, easy to clean, and re-use, subject in efficient illumination, and the materials are readily available so that the fabrication is easy and scalable.

Using the transparent polyethylene bag with cut-out plastic jug for its support are the inventive technology developed by the team as the PBR housing or the culturarium for algae. Part of their worked on photobioreactor systems is the involvement of prototypes designed to probe the effects of various parameters on microalgae growth in terms of the modification of culture media, light configuration and its culture process. As a result, the alpha PBR prototype showed a significant increase in growth rates in terms of cell count and cell size of Spirulina. The cost of power used for lighting system was low; the culture time was decreased and created as highest biomass yield improvement with approximately 70 percent increase in microalgae production.

The developed PBR system is now being undertaken by the Alsons Aquaculture Corporation, an industry partner based in Sarangani, Province, and one of the major aquaculture companies in the Philippines. The optimized PBR system and culture condition of Spirulina are transferred to Alsons where it will be scaled-up, further optimized and pilot tested to make the product market-ready. ### (Leoveliza C. Fontanil)

Source: bar.gov.ph

Spirulina (Arthrospira platensis) or the blue-green photosynthetic microalgae, known as the highest natural protein source, contains about 55-70 percent essential protein profile with a complete set of key compounds such as amino acids, polyunsaturated fatty-acids (PUFA’s), carotenoids, and vitamins A, C, D, E, B12 or cobalamin that boost the required nutritional diet of fish. One of the characteristics of this quality feed is the presence of natural constituents that has high value of nutraceuticals. These compounds include omega-3 fatty acids, carbohydrates, dietary minerals, and phycobiliproteins.

Due to its boundless nutrient contents, Dr. Dayrit highlighted the main benefits of feeding Spirulina for aquaculture purposes. Among the benefits include: 1) increase and give a more uniform growth rate for fish; 2) improve the digestion; as a result of more nutrition are extracted from the food and there are no indigestible components; 3.) boost the immune system and aid prevention of swollen abdomens due to blocked intestinal passages; and 4) enhance production of special enzymes that break down digested fats into energy rather than letting them build up in the fishes body.

Seeing its importance, Dr. Dayrit and his team fabricated an optimized PBR system and culture condition for the production of Spirulina. Unlike other PBR designs for algae growth, the features of developed enhance PBR are inexpensive, easy to clean, and re-use, subject in efficient illumination, and the materials are readily available so that the fabrication is easy and scalable.

Using the transparent polyethylene bag with cut-out plastic jug for its support are the inventive technology developed by the team as the PBR housing or the culturarium for algae. Part of their worked on photobioreactor systems is the involvement of prototypes designed to probe the effects of various parameters on microalgae growth in terms of the modification of culture media, light configuration and its culture process. As a result, the alpha PBR prototype showed a significant increase in growth rates in terms of cell count and cell size of Spirulina. The cost of power used for lighting system was low; the culture time was decreased and created as highest biomass yield improvement with approximately 70 percent increase in microalgae production.

The developed PBR system is now being undertaken by the Alsons Aquaculture Corporation, an industry partner based in Sarangani, Province, and one of the major aquaculture companies in the Philippines. The optimized PBR system and culture condition of Spirulina are transferred to Alsons where it will be scaled-up, further optimized and pilot tested to make the product market-ready. ### (Leoveliza C. Fontanil)

Source: bar.gov.ph